In today's rapidly evolving industrial landscape, the advent of Glass Shell technology is poised to revolutionize

manufacturing and design standards. According to a recent report by the International Data Corporation (IDC), industries that integrate advanced materials like

Glass Shell are expected to see a 25% increase in operational efficiency by 2025. This innovative approach leverages

data-driven insights to enhance product durability, aesthetics, and functionality, setting a new benchmark for precision engineering. As sectors

such as automotive, electronics, and construction increasingly adopt Glass Shell technology, organizations are not only meeting consumer demands for sustainability

and performance but are also gaining a competitive edge in the market.

This blog explores the multifaceted advantages of Glass Shell technology and how its implementation can drive transformative changes across various industries.

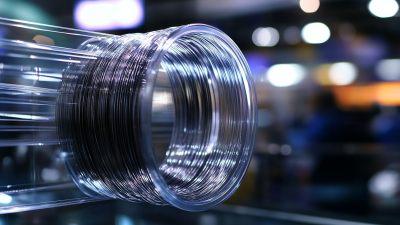

Glass Shell Technology is an innovative advance in the realm of materials science, characterized by its unique structure and benefits. At its core, this technology involves the use of thin, durable glass layers that encapsulate various components, providing a protective yet transparent barrier. This characteristic not only enhances the aesthetic appeal of products but also significantly boosts their resilience against environmental stressors such as moisture and dust. The ability to seamlessly integrate these glass shells into existing systems sets the stage for a plethora of applications across different industries, from consumer electronics to automotive manufacturing.

By leveraging data-driven insights, industries can unlock the full potential of Glass Shell Technology. Understanding key concepts such as thermal resistance, light transmission, and mechanical strength is crucial for optimizing designs and usage. With the integration of smart sensors within glass structures, real-time data collection becomes possible, allowing for continuous monitoring and adaptive response to changing conditions. This level of insight not only improves product performance but also drives sustainability by reducing waste and increasing longevity, ultimately transforming industry standards and paving the way for innovative solutions that meet modern challenges.

The integration of glass shell technology into industrial processes is rapidly gaining momentum, propelled by data-driven insights that enhance its implementation. A recent report from MarketsandMarkets indicates that the glass manufacturing industry is projected to reach $700 billion by 2025, driven largely by innovations like glass shell technology. These advancements not only improve product durability but also optimize production efficiency. Incorporating real-time data analytics can lead to predictive maintenance and reduction in material waste, achieving up to 30% cost savings as reported in a McKinsey study.

Tips for successfully employing data-driven insights include investing in robust data collection systems that track performance metrics across the production cycle. This data can reveal inefficiencies and guide R&D efforts for future innovations. Furthermore, fostering a culture of continuous improvement among employees helps to capitalize on the insights generated, leading to operational excellence.

Adopting a comprehensive data strategy is essential for companies looking to stay ahead in the glass shell technology space. Utilizing machine learning algorithms can identify patterns in production data that might not be apparent through traditional analysis. This analytical approach can not only streamline processes but also spur innovative applications of glass shell technology across various industries, from automotive to consumer electronics.

As industries increasingly seek innovation, glass shell technology emerges as a transformative force. When evaluating its benefits, it is essential to consider its potential impacts on durability and functionality. A recent report by MarketsandMarkets predicts that the global demand for glass-based materials in the manufacturing sector is expected to reach $100 billion by 2025, with a CAGR of 7.5%. This growth is driven by the technology's inherent resistance to corrosion, high temperatures, and weight advantages, making it suitable for sectors ranging from electronics to construction.

In assessing glass shell technology for your industry, a checklist can be pivotal. First, analyze the cost-benefit ratio: While initial investments might be higher, the long-term savings on maintenance and replacement can be substantial. For example, according to a study by the American Society of Civil Engineers, buildings utilizing glass in their architecture report a 25% reduction in energy costs. Additionally, consider the potential for sustainability; glass is fully recyclable and can significantly decrease the carbon footprint of products. Companies adopting this technology are not only enhancing their operational efficiency but also aligning with global sustainability goals.

The adoption of glass shell technology in various industries can present a unique set of challenges, yet the potential benefits make it a worthwhile consideration. According to a recent report by MarketsandMarkets, the glass packaging market is expected to grow from $66.9 billion in 2021 to $106.4 billion by 2026, highlighting the increasing relevance of innovative glass solutions. One of the main challenges organizations face is the high initial investment and the need for skilled personnel to manage the transition.

Tip: Conduct a thorough cost-benefit analysis to understand the long-term returns on investing in glass shell technology. This can help justify initial expenditures and demonstrate value to stakeholders.

Additionally, integrating glass shell technology requires overcoming operational hurdles such as supply chain adjustments and employee re-training. A survey from Deloitte found that 70% of organizations struggle with change management during technology implementation. To alleviate these issues, it's essential to develop a structured adoption plan that includes targeted training sessions and a phased rollout strategy.

Tip: Engage with a cross-functional team when developing your implementation strategy to ensure diverse perspectives are included, ultimately leading to a smoother transition.

| Dimension | Data Point | Implications |

|---|---|---|

| Energy Efficiency | 30% reduction in energy consumption | Lower operational costs and reduced carbon footprint |

| Durability | 2x stronger than traditional materials | Increased lifespan of products, reduced replacement frequency |

| Market Adoption Rate | 20% annual growth | Rapid shift in industry standards towards modern materials |

| Cost Implications | 15% initial investment increase | Long-term savings outweigh initial costs |

| Customization | High flexibility in design | Enhanced capabilities in product differentiation and branding |

The rapid evolution of glass shell technology is poised to make a significant impact across various industries, particularly within electronics, construction, and automotive sectors. According to a recent report by MarketsandMarkets, the global glass technology market is projected to reach $174 billion by 2025, growing at a CAGR of 8.3%. This growth is driven by the increasing demand for eco-friendly materials and advanced manufacturing processes. As industries adopt data-driven insights to leverage the unique properties of glass, we can expect enhanced product designs and improvements in functionality.