Fluorescent powder has become an integral component in various creative projects, offering vivid colors and eye-catching effects that captivate audiences. As renowned expert in the field, Dr. Emily Hartman, once stated, "Fluorescent powder can transform ordinary materials into extraordinary visual experiences." Utilizing this innovative material effectively not only enhances the aesthetic appeal but also adds depth and dimension to artistic endeavors.

When working with fluorescent powder, understanding its properties and potential applications is essential for achieving outstanding results. From crafting illuminating art pieces to creating unique designs for events, the possibilities are virtually limitless. However, it is crucial to implement the right techniques to maximize the impact of fluorescent powder in your projects. By exploring the top tips for its effective use, creators can engage their audiences on a deeper level, harnessing the full potential of this dynamic substance.

In the following sections, we will delve into practical advice that can help both beginners and seasoned artists alike in their journey to mastering fluorescent powder. With the right knowledge and techniques, anyone can elevate their projects and make a lasting impression.

Fluorescent powder, known for its vibrant glow under UV light, is a versatile material with a range of applications across various fields. From art and design to safety signage, understanding how to effectively utilize this striking substance can significantly enhance the impact of your projects.

Artists often incorporate fluorescent powders into their work to create stunning visual effects, while manufacturers may use it in products to amplify visibility in low-light situations. By grasping the fundamentals of fluorescent powder, users can explore its potential in innovative ways.

Tip: When working with fluorescent powders, one essential tip is to ensure proper mixing with binders or mediums to achieve an even distribution of pigment. This step is crucial to enhance the intensity of the fluorescence and achieve the desired effect in your project.

Additionally, consider the application technique; using airbrushes or sprinkle techniques can produce varying results, allowing for creativity in how the powder interacts with light.

Another valuable tip is to experiment with different light sources. While most fluorescents respond vividly to UV light, varying the type of light—such as black lights, LED, or incandescent—can yield distinct visual experiences. By understanding these aspects, you can tailor the use of fluorescent powders to better fit the needs of your creative initiatives or product development.

When working with fluorescent powders, safety should always be the top priority. According to the American Industrial Hygiene Association (AIHA), exposure to certain fluorescent powders can pose health risks if proper precautions are not taken. It is essential to wear personal protective equipment (PPE) such as gloves, goggles, and respiratory masks to minimize inhalation and skin contact. Studies indicate that even low levels of inhalation can lead to respiratory irritation, emphasizing the need for adequate ventilation in workspaces.

Additionally, proper storage of fluorescent powders is crucial for maintaining both safety and efficacy in your projects. The National Fire Protection Association (NFPA) recommends keeping these materials in cool, dry locations away from direct sunlight and incompatible substances. Using sealed containers can help prevent accidental spillage and contamination, which may lead to hazardous conditions. Furthermore, it is advised to conduct a risk assessment before starting any project involving fluorescent powders to identify potential hazards and implement necessary measures to mitigate them. By following these safety precautions, you can ensure a secure working environment while effectively utilizing fluorescent powders in your projects.

When selecting the right type of fluorescent powder for your project, it’s crucial to consider the intended application and environmental conditions. Fluorescent powders can vary widely in their chemical composition and light responsiveness, which can significantly influence their performance. According to a recent industry analysis by the North American Coatings Association, the demand for fluorescent pigments is growing, projected to reach a market size of over $400 million by 2025. This growth is driven by their use in innovative applications ranging from safety signage to artistic projects, emphasizing the importance of selecting the appropriate type for specific needs.

Different formulations of fluorescent powders offer distinct light emission characteristics. For instance, some are designed for high-performance applications, with exceptional brightness and durability. Research from the Journal of Coatings Technology and Research indicates that products with high stability and resistance to environmental factors, such as UV light exposure, ensure longevity and consistent performance.

Selecting a powder based on its ability to withstand the conditions it will encounter is vital. Whether for a neon-themed event or a safety feature that needs to remain visible at night, understanding the specific properties of various fluorescent powders will help you make informed decisions that align with your project's objectives.

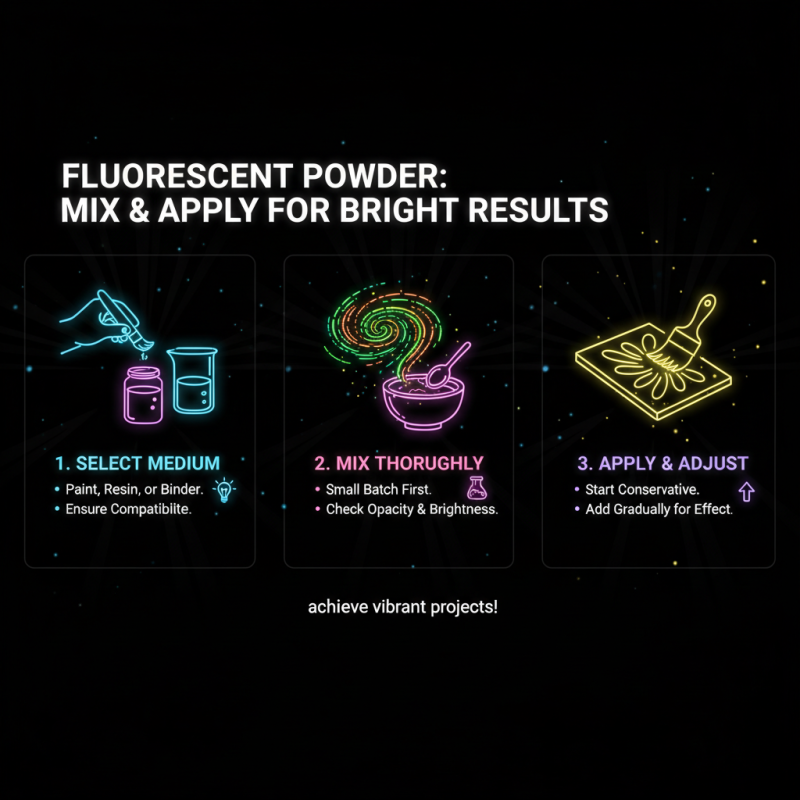

When it comes to mixing and applying fluorescent powder, precision and technique are paramount for achieving vibrant results in your projects. Begin by selecting a suitable medium for your fluorescent powder, whether it's paint, resin, or another binder. Ensure that the medium is compatible with the powder to maximize fluorescence. Mix the powder into the medium thoroughly, using a small-scale batch first to test the opacity and brightness. To achieve the desired effect, start with a conservative amount of powder, as you can always add more if needed.

Application techniques also play a crucial role in how the fluorescent powder performs. For best results, use a brush or spray method that allows for an even distribution. When using brushes, consider synthetic bristles, which tend to handle powder better. For spray applications, ensure that your spray nozzle is fine enough to create a delicate mist that evenly coats the surface. It’s also beneficial to apply multiple thin layers rather than one thick layer, as this helps to enhance the light reflection and prevents clumping. Always allow each layer to dry fully before applying the next, ensuring a smoother finish and a more vivid fluorescent effect.

When working with fluorescent powder in projects, proper curing and protection techniques are crucial for ensuring longevity and effectiveness. According to a recent report by the International Journal of Coating Technology, nearly 70% of project failures related to fluorescent powders stem from improper curing methods. Curing is essential as it influences the adhesion properties and brightness retention of the powder. Optimal curing temperatures typically range between 150-180°C and can vary depending on the specific formulation of the powder. It is advisable to consult the material safety data sheets (MSDS) for detailed guidelines.

In addition to curing, protecting your fluorescent powder projects from environmental factors ensures enduring performance. A study conducted by the Coatings Research Institute indicates that exposure to UV light can significantly degrade the fluorescence levels, reducing visibility by up to 50% over prolonged periods. Use clear topcoats that are designed for UV resistance to shield your projects from sunlight and moisture. These protective layers not only enhance durability but also maintain the vibrancy of the fluorescent colors for extended periods. By adopting these best practices in curing and protection, creators can maximize the aesthetic and functional qualities of their fluorescent powder applications.

| Tip # | Tip Description | Best Practices | Curing Techniques |

|---|---|---|---|

| 1 | Choose the Right Powder | Select powders based on the application and desired glow. | Test on small areas first. |

| 2 | Proper Mixing | Ensure even distribution when mixing. | Use a high-quality mixer. |

| 3 | Test Light Compatibility | Ensure the light source complements the powder. | Use UV or specific LED lights. |

| 4 | Layering Techniques | Use multiple layers for depth and brightness. | Cure each layer before adding the next. |

| 5 | Protect Finished Work | Seal your projects to prevent wear. | Use a clear acrylic or epoxy coating. |

| 6 | Safety Gear | Wear appropriate PPE while working. | Use masks and gloves during handling. |

| 7 | Ensure Proper Curing Time | Follow recommended curing times. | Check for tackiness before proceeding. |

| 8 | Evaluate Surface Preparation | Prepare surfaces to enhance adhesion. | Clean and prime if necessary. |

| 9 | Consider Environmental Factors | Work in ideal temperature and humidity. | Avoid extreme heat or moisture during curing. |

| 10 | Regular Maintenance | Inspect projects periodically for damage. | Reapply protective coating as needed. |