The Glass Shell has emerged as a fascinating innovation in various industries. It serves multiple purposes, often blurring the line between design and functionality. This unique structure consists of lightweight, transparent materials, providing an aesthetic appeal and practical applications.

In architecture, the Glass Shell creates stunning facades that allow natural light to flood in. Its transparency invites the outside world, promoting a sense of openness. However, using a Glass Shell requires careful consideration of temperature control and energy efficiency. There are challenges in maintaining comfort levels in extreme weather conditions.

Beyond architecture, the Glass Shell finds use in technology. It protects delicate equipment while allowing visibility. However, the fragility of glass presents dilemmas in terms of durability and safety. There’s a constant need to balance beauty with function. Overall, the Glass Shell is a captivating topic that invites discussion about innovation and its practical implications.

A glass shell is a type of structural component made entirely of glass. This innovative design offers unique properties that set it apart from traditional materials. It is often lightweight yet robust, providing excellent durability. Reports indicate that the glass shell market is projected to grow significantly, with a CAGR of 7.5% over the next five years.

These shells come with thermal insulation benefits, making them ideal for energy-efficient buildings. Research from industry experts shows that glass shells can enhance natural light within a space, promoting a healthier environment. However, it's crucial to address the potential challenges. Glass can be prone to cracking under pressure, a concern that requires careful engineering and design.

The aesthetic appeal of a glass shell cannot be overlooked. Its transparency allows for seamless integration with various architectural styles. Yet, the cost remains a major factor. High-quality glass materials can lead to significant investments. As the industry advances, innovation and sustainable practices will play pivotal roles in shaping the future of glass shell applications.

The glass shell technology has undergone significant evolution over the years. Early forms of glass shells were simple structures used for decorative purposes. As processes advanced, their application expanded into fields like architecture and lighting. The adaptability of glass made it a favored material among artists and engineers.

During the 20th century, glass-making techniques improved dramatically. This led to the creation of more complex shapes. Innovations like tempered and laminated glass enhanced durability. These developments enabled glass shells to serve functional roles, like in buildings and vehicles. However, challenges arose in balancing aesthetics with structural integrity.

Tip: When incorporating glass shells in design, consider both function and safety. Test various thicknesses to find the ideal balance.

The modern approach emphasizes sustainability. Yet, many still struggle with wastage during production. Efforts to minimize this are essential. The future looks promising as technology continues to evolve. Embracing these innovations can lead to smarter designs.

Tip: Stay updated on materials science. New discoveries can transform how we think about glass.

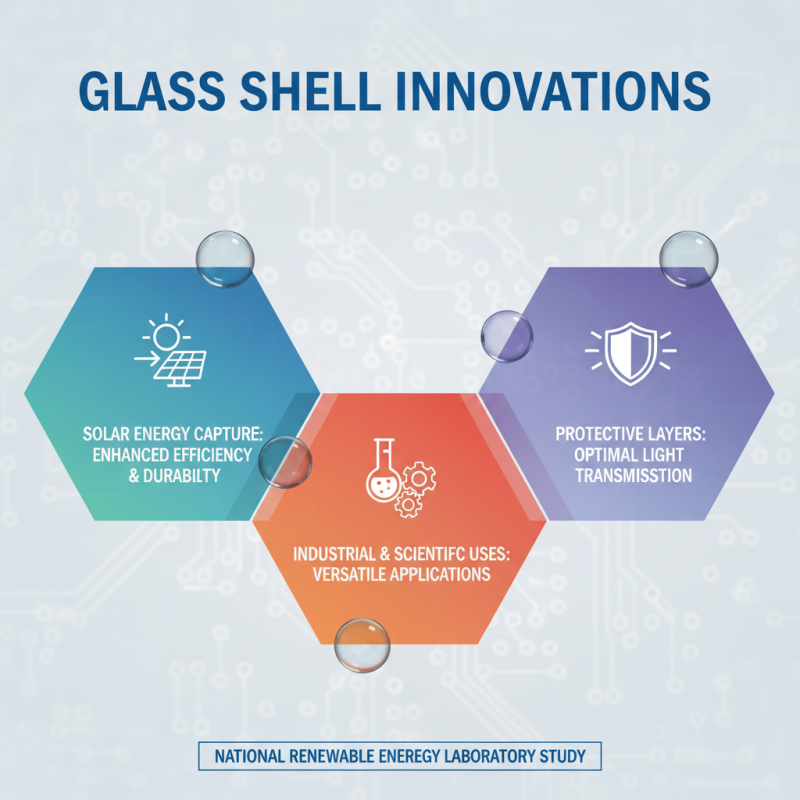

Glass shells have diverse applications across various industries and scientific fields. In the energy sector, glass shells are often used for solar energy capture. A study by the National Renewable Energy Laboratory indicates that the efficiency of solar panels can improve significantly when employing glass shells as protective layers. These shells enhance durability while maintaining transparency. This allows for better light transmission, which is crucial for energy absorption.

In the field of pharmaceuticals, glass shells are utilized in encapsulation processes. They serve to protect sensitive compounds from degradation. According to a report by the International Journal of Pharmaceutics, using glass shells improves the stability of certain drugs, leading to extended shelf life. However, challenges remain. The cost of producing high-quality glass shells can be prohibitive for some manufacturers. Plus, the potential fragility of these shells may lead to product loss during packaging and transportation.

Additionally, glass shells find use in electronics. They provide insulation and protection for sensitive components. A report from Semiconductor Manufacturing International Corporation suggests that utilizing glass shells in semiconductor devices can reduce material waste by up to 30%. However, the manufacturing process can be complex. Inconsistent quality can result in defects that undermine the advantages of using glass shells. These hurdles highlight the need for ongoing research and improvement in the production techniques employed.

Glass shells have gained popularity due to their unique properties. These structures are often used in various industries, from architecture to electronics. The technical specifications of glass shells can vary widely. Common thickness ranges from 3mm to 15mm, depending on the application. The tensile strength of glass is impressive; it can be up to 140 MPa. Such strength makes glass an ideal choice for both aesthetic and functional applications.

Manufacturing processes for glass shells encompass multiple steps. They may involve melting raw materials at high temperatures, typically around 1700 degrees Celsius. Once molten, glass is shaped into a shell using molds. This can lead to imperfections. For instance, bubbles can form during the cooling process, impacting clarity. Additionally, the cooling rate is crucial. Too fast, and the glass may crack; too slow, and it may distort.

A report by the Glass Industry Association indicates that the demand for glass shells is expected to grow by 5% annually. Innovations in manufacturing techniques may improve quality but may also introduce new challenges. As producers strive for perfection, the balance between efficiency and quality remains a key concern. The glass shell industry must continually adapt and improve while managing the inherent flaws in the material.

This chart illustrates key technical specifications related to glass shell manufacturing. The values indicate typical parameters used during production, including the melting temperature of glass, cooling time, thickness of the shells, and production rate.

The future of glass shell design is fascinating. Innovations are emerging across various sectors, blending aesthetics with functionality. Architects now envision structures that use glass shells to enhance natural light while maintaining energy efficiency. This trend promotes sustainability in building design.

Tips: Consider how natural light impacts mood. Glass shells can create bright spaces that boost productivity.

New techniques allow for intricate designs that were once impossible. Designers experiment with curved and layered glass, allowing for unique shapes. These innovations enable buildings to reflect the surrounding environment more harmoniously. This is a step toward a more integrated approach to architecture.

Tips: Think about transparency. Glass shells can blur the lines between indoor and outdoor spaces, fostering a connection with nature.

As we explore new materials and technologies, challenges arise. Durability and maintenance remain vital considerations. Designers must balance these factors with creative vision. The future may hold breakthrough solutions, transforming how we think about glass in architecture.

| Dimension | Description |

|---|---|

| Material Type | Borosilicate glass, tempered glass, laminated glass |

| Applications | Architectural facades, protective covers, display cases |

| Innovations | Smart glass, self-cleaning surfaces, integrated lighting |

| Trends | Sustainability, energy efficiency, aesthetic versatility |

| Market Outlook | Increasing demand in architectural and automotive industries |