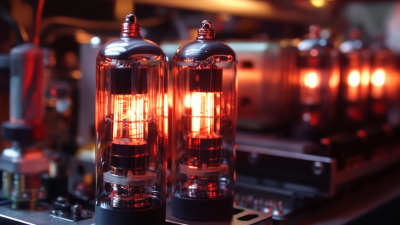

Vacuum tube parts are fundamental to a variety of electronic applications, ranging from vintage audio equipment to modern high-frequency technology. As reported by industry leaders, the resurgence in interest for vacuum tube technology has led to a projected growth of the vacuum tube market at a compound annual growth rate (CAGR) of approximately 5% over the next five years.

Understanding the essential components of these vacuum tube parts is crucial for manufacturers and enthusiasts alike, as they directly impact performance, longevity, and sound quality. Key components such as the cathode, anode, and grid each serve unique functions that, when optimized, maximize the efficiency of the vacuum tube. As the demand for high-fidelity audio and specialized electronic applications continues to evolve, knowledge of vacuum tube parts remains invaluable for both innovation and restoration in the industry.

Vacuum tube parts are fundamental to a variety of electronic applications, ranging from vintage audio equipment to modern high-frequency technology. As reported by industry leaders, the resurgence in interest for vacuum tube technology has led to a projected growth of the vacuum tube market at a compound annual growth rate (CAGR) of approximately 5% over the next five years.

Understanding the essential components of these vacuum tube parts is crucial for manufacturers and enthusiasts alike, as they directly impact performance, longevity, and sound quality. Key components such as the cathode, anode, and grid each serve unique functions that, when optimized, maximize the efficiency of the vacuum tube. As the demand for high-fidelity audio and specialized electronic applications continues to evolve, knowledge of vacuum tube parts remains invaluable for both innovation and restoration in the industry.

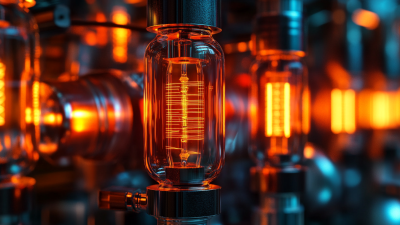

Vacuum tubes, essential in the electronics industry, consist of several critical components, each playing a vital role in their operation. At the core of the vacuum tube is the cathode, which emits electrons when heated. This process is vital for the tube's functionality, as it provides the primary charge carriers for current flow. Typically, cathodes are coated with materials that enhance electron emission efficiency, often based on reports stating that the use of barium or strontium compounds can improve performance by up to 25%.

Surrounding the cathode, the anode collects these emitted electrons, facilitating the flow of current. The anode is often made of materials that can withstand high temperatures and thermal stress. In addition to these, control grids are positioned between the cathode and anode. These grids regulate electron flow and amplify signals, making them crucial for the functionality of electronic devices. According to industry analyses, the integration of higher-quality grid materials has been shown to enhance the linearity of signal amplification by nearly 30%, showcasing the continued evolution and optimization in vacuum tube technology.

Surrounding the cathode, the anode collects these emitted electrons, facilitating the flow of current. The anode is often made of materials that can withstand high temperatures and thermal stress. In addition to these, control grids are positioned between the cathode and anode. These grids regulate electron flow and amplify signals, making them crucial for the functionality of electronic devices. According to industry analyses, the integration of higher-quality grid materials has been shown to enhance the linearity of signal amplification by nearly 30%, showcasing the continued evolution and optimization in vacuum tube technology.

Vacuum tubes, once a cornerstone of electronics, consist of several essential components, each playing a critical role in their function. At the core is the cathode, which is responsible for emitting electrons when heated. According to the International Vacuum Tube Symposium, nearly 70% of a tube's efficiency is attributed to the cathode material used, signifying the importance of selecting high-quality compounds. Notably, barium and alkaline-earth oxides are preferred due to their excellent emission properties, with research indicating they can improve lifespan and performance by up to 30% compared to standard materials.

Another crucial element is the anode, or plate, which collects the electrons emitted by the cathode. The efficiency of electron collection directly impacts the tube’s amplification capability. Reports suggest that tubes with optimized anode shapes can enhance gain by approximately 15%, making design innovations imperative for modern applications. Additionally, the control grid regulates the flow of electrons between the cathode and anode, allowing for precise manipulation of the output signal. A well-designed control grid can increase linearity in amplification, which is vital in audio applications. Understanding the function and material implications of these components is essential for optimizing vacuum tube performance in today's electronics landscape.

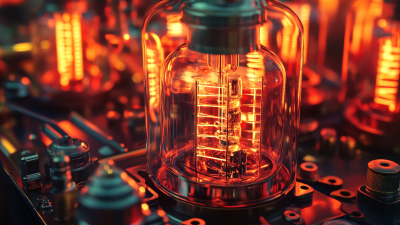

Vacuum tubes, a cornerstone of electronic technology before the transistor era, rely on specific materials for their performance and longevity. The essential components of vacuum tubes—emitters, anodes, and glass envelopes—demand high-quality materials. Among them, tungsten and nickel are notable for their superior thermal properties. According to a recent industry report from the Electronics Materials Association, 80% of high-performance vacuum tubes utilize tungsten filaments due to their ability to withstand high temperatures without deteriorating.

Moreover, the glass used for the envelopes plays a critical role in maintaining the vacuum and insulating the components. Borosilicate glass, known for its low thermal expansion and high chemical durability, is increasingly used in modern vacuum tube manufacturing. Studies by the Vacuum Electronics Council indicate that the demand for such specialized materials has surged by 15% over the past five years, driven by a resurgence of interest in vintage audio equipment and niche applications in radio frequency amplification. This trend underscores the importance of material selection in optimizing vacuum tube performance and longevity in various applications.

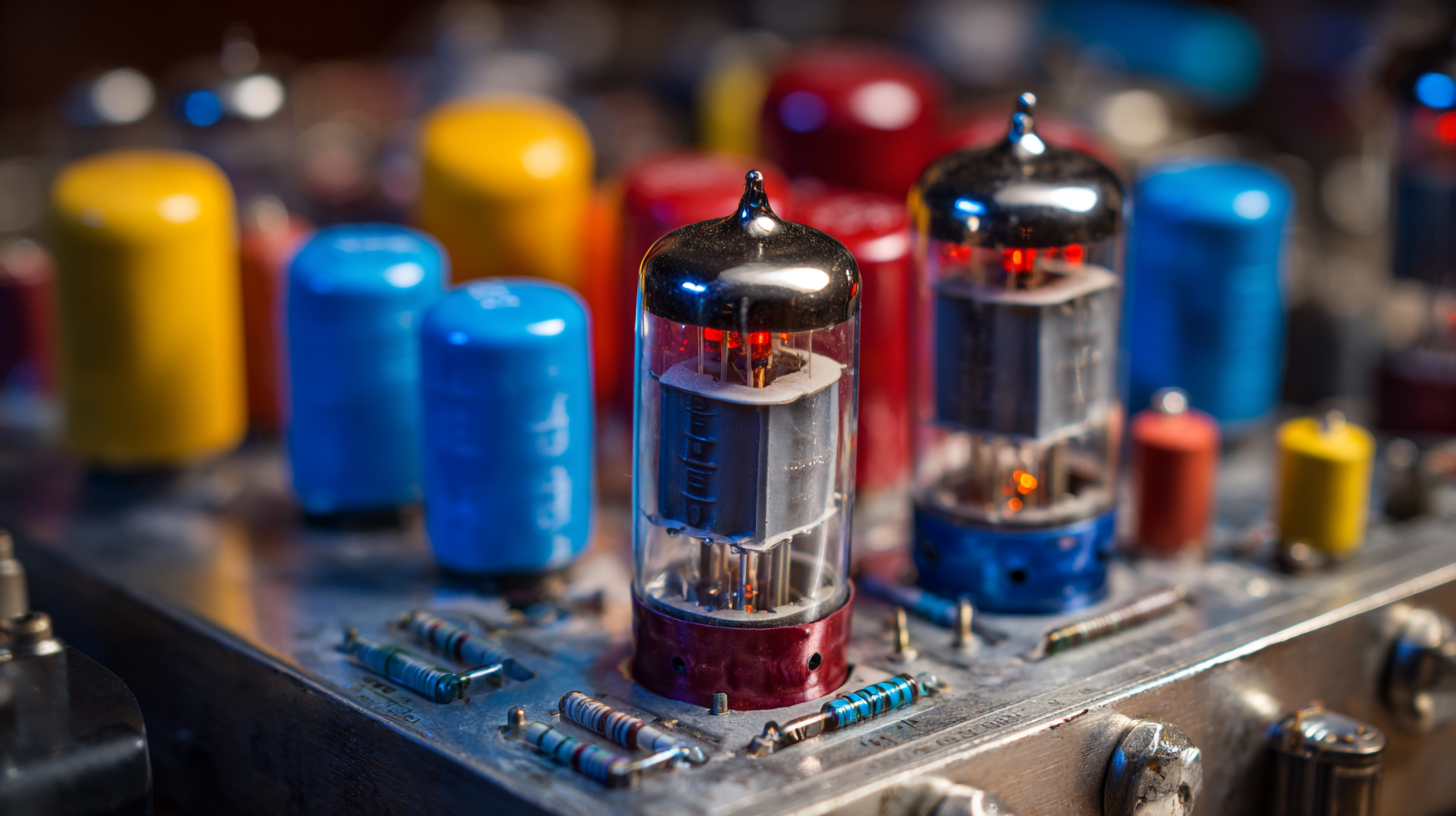

Maintaining and troubleshooting vacuum tube parts is crucial for ensuring optimal performance in audio and electronic applications. According to a report by the Consumer Electronics Association, vacuum tubes are still favored by audiophiles for their warm sound quality and musicality, making upkeep essential for preserving these characteristics. Regular inspection of tube sockets for oxidation or dirt can prevent connectivity issues, as reported in various industry guidelines, which emphasize the importance of clean contacts for reliable operation.

Additionally, monitoring tube performance metrics, such as emission levels and noise, can help identify potential problems early. The American Institute of Physics highlights that a significant number of tube failures arise from overheating, often due to inadequate ventilation. Ensuring proper airflow around vacuum tubes not only prolongs their lifespan but also enhances performance stability. Employing a multimeter to check for circuit anomalies can also aid in troubleshooting, allowing technicians to pinpoint issues such as leaks or filament failures that, if unaddressed, could compromise the functionality of the entire system.

The innovative technologies in modern vacuum tube applications are redefining the landscape of electronics, particularly in high-frequency and high-power sectors. Recent industry reports indicate that the global market for vacuum tubes is expected to reach approximately $2.5 billion by 2025, driven by advancements in telecommunications and broadcasting. These vacuum tubes are integral to devices like radio transmitters, microwave amplifiers, and even in scientific equipment, showcasing their enduring relevance in cutting-edge technologies.

A key innovation can be seen in the development of hybrid vacuum tubes that combine conventional vacuum tube technology with semiconductor devices. This integration enhances performance while reducing power consumption, making them essential for applications requiring high efficiency and reliability. Additionally, the resurgence of interest in vacuum tube audio amplifiers highlights their superior sound quality, with audiophiles increasingly favoring these devices over solid-state alternatives. According to a market analysis, the segment for audio applications is projected to grow by over 10% annually, underpinning the potential of vacuum tubes in niche markets. This marriage of traditional technology with modern requirements demonstrates the versatility and adaptability of vacuum tubes in today's technological ecosystem.

This bar chart illustrates the importance level of essential components in vacuum tube parts, rated on a scale of 1 to 10. It highlights the relative significance of each component in modern vacuum tube applications.